The usage of cartons and corrugated sheets is widespread in the packaging industry. These corrugated sheets are used in the production process of cartons, corrugated boxes, paper bags, and other related packaging products. These packaging products are used all across the world for the shipment and storage process of various kinds of items that may be sensitive in nature. To ensure that the packaged items remain intact and do not get contaminated or damaged, it becomes extremely important for manufacturers to opt for a stronger packaging layer.

The corrugated boxes that are used as packaging layers must be durable enough to withstand shipment & storage issues at all stages. However, assessing the durability of these boxes & cartons after their production can cause losses to the manufacturer of the brand as these productions take place in bulk sizes. Hence, uncertainties after a point are a bigger issue because of the already-spent resources in the production process. To avoid such issues, the Presto Group offers a high-class lab testing instrument that allows the operator to assess the quality of corrugated sheets which will later turn into corrugated boxes.

The lab testing instrument that evaluates the rupturing factor of a corrugated sheet is called the bursting tester. The instrument is designed to assess the ability of a corrugated sheet to avoid rupturing which is the major reason for damaging items during shipment and storage processes.

The simplistic working module of the instrument has attracted manufacturers in huge numbers as it ensures seamless testing without any trouble.

The burst strength tester is equipped with an ergonomic testing design as it follows a hydrostatic mechanism to conduct the test with maximum accuracy & precision levels.

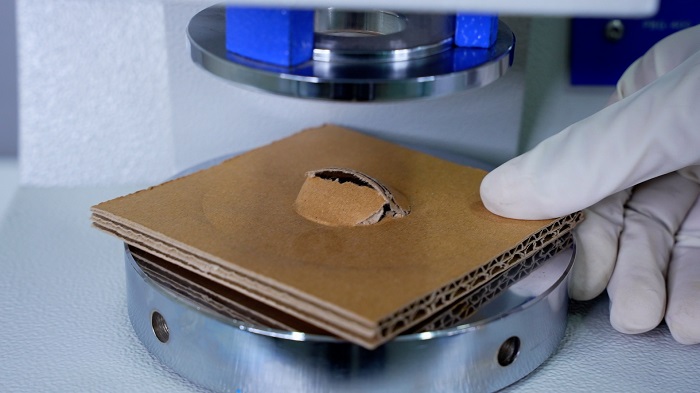

To begin with the test, the operator must adjust the specimen among the grippers of the instrument situated just above the diaphragm made of neoprene rubber of the bursting testing machine.

The specimen is clamped firmly with the help of the rotating wheel and made sure that it does not move during the course of testing. Afterward, the instrument is turned on with the help of the dedicated switches on the control panel. This leads to the activation of the lab-grade glycerine present below the diaphragm to force pressure on the specimen. The pressure exerted on the diaphragm results in the expansion of the diaphragm.

The expansion of the diaphragm is directed toward the specimen clamped, the specimen withstands the pressure exerted due to the expansion of the diaphragm but results in rupturing or bursting after the peak load.

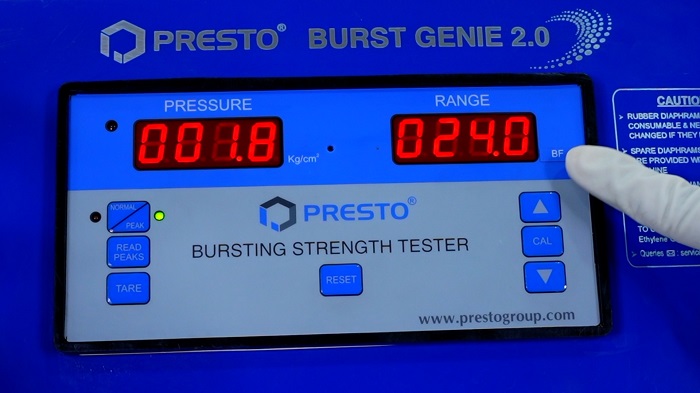

The microprocessor-based digital display indicates the results achieved from the testing apparatus and determines the bursting factor with extreme ease & facile.

The bursting strength tester is equipped with a lot of features that ensure this testing process to be seamless and avoids all kinds of hassle.

The paper burst strength tester offers top-quality features and enhances the testing standards of the operator.

The most prominent feature of the paper burst strength tester that has captured the attention of manufacturers is the incorporation of top-notch neoprene rubber as the diaphragm of the instrument. This material allows the operator to conduct testing with absolute facile and achieve highly accurate results because of its durability and longevity.

The bursting testing machine is also offered with a rotary clamping mechanism that is highly necessary for the firm & strong clamping of the specimen as it makes sure that the specimen doesn’t move when the testing process is underway.

The microprocessor-based digital display of the instrument indicates the bursting strength of the specimen through which the operator can simply determine the bursting factor of the specimen.

Another top-quality feature is the inculcation of lab-grade glycerine below the diaphragm of the burst strength tester allows the operator to conduct all the burst tester applications with facile and also triggers the hydrostatic pressure mechanism of the instrument.

The robust construction of the burst strength tester also plays a pivotal role in attracting manufacturers from the rigid paper & packaging industry. The firm build is empowered with mild steel material coated with a 7-layered powder paint that ensures the anti-rusting properties of the instrument.

To achieve higher levels of accuracy in determining the bursting strength & bursting factor of a corrugated sheet, you can get yourself the top-notch burst strength tester. To seek further information regarding the burst tester applications you can feel free to visit our website and attain knowledge about this or other lab testing instruments.

To book yourself this top-quality lab testing equipment, you can find us by calling at +91 9210903903 or directly e-mail us at info@prestogroup.com. The company strives forward to serve you with cutting-edge technology.

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?