Of all the fragile articles to be packed, light bulbs have to be the most susceptible to damage. From manufacturer to consumer, light bulbs are easily broken due to various factors that may come into play during transit or storage. It could either be from rough handling or stacking pressure, it is of utmost concern for manufacturers and distributors to make sure that these products are not damaged.

This is where the Presto’s ECT tester comes into play. The strength assessment of the corrugated materials used in packaging ensures that delicate items like bulbs do not break, bringing down damage, and costs, and increasing customer satisfaction.

Light bulbs, especially glass bulbs, are very sensitive to pressure. A single mistake in handling or transport can result in broken glass, broken parts, or defective products reaching the customer. Bulbs undergo a lot of stress from external forces, especially when stacked or compressed. If not packaged properly, these delicate items are likely to suffer damage from the vertical pressure that is applied in transit or storage.

This has prevented corrugated fiberboard from being the material of choice for packaging bulbs. It is a product that balances protection with lightweight, ensuring that the bulbs are safely cushioned.

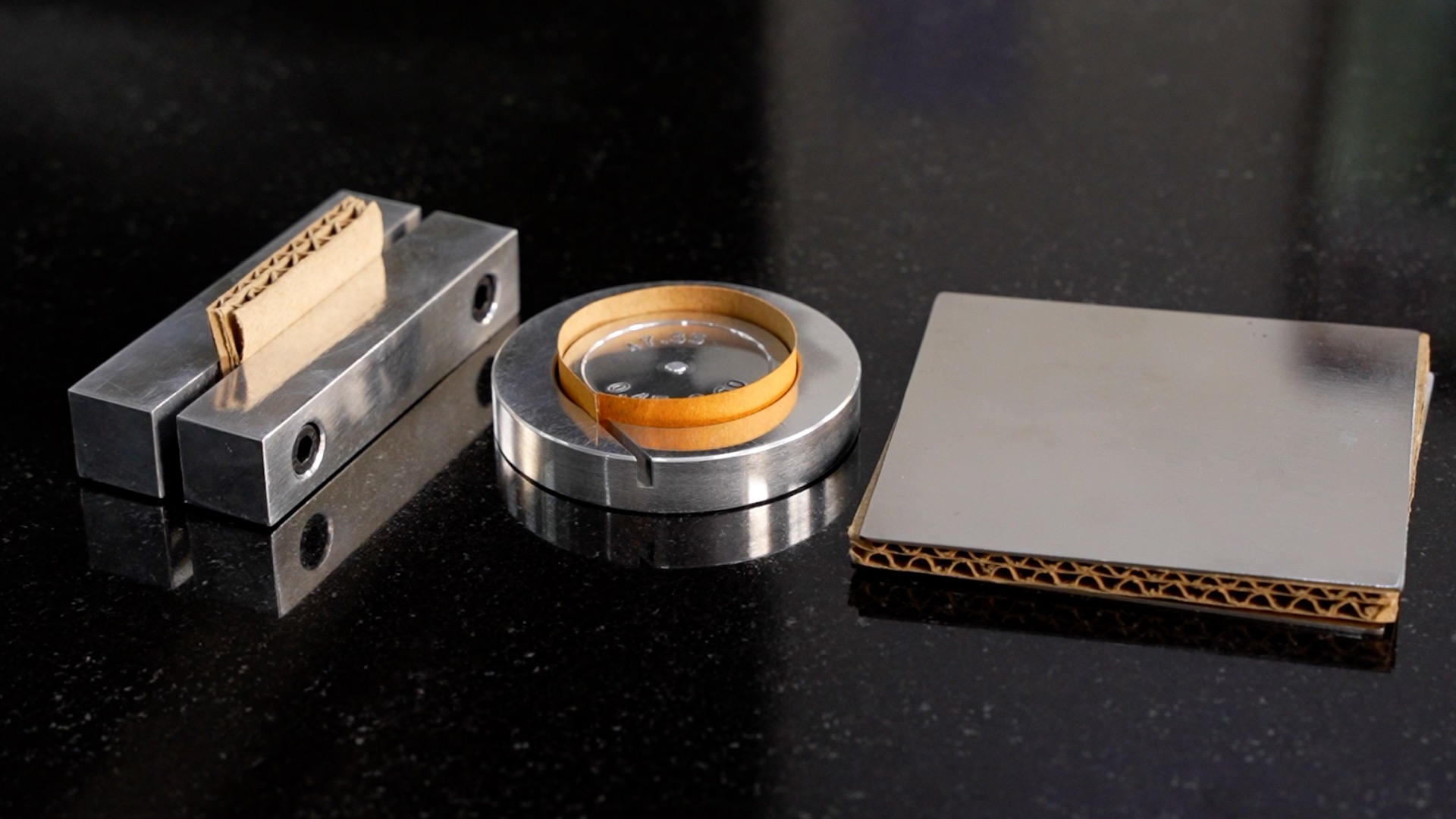

ECT refers to the Edge Crush Tester, a device through which the edge compression strength of the corrugated cardboard material along with its stacking strength is determined. An edge crush test determines how much vertical compressive pressure a corrugated board can withstand when pressed on top of an underlying cardboard.

Its principal goal is to ensure that packaging integrity is maintained to prevent damage to products being placed inside from the force exerted by stacking. The ECT helps establish the strength of the packaging material by applying a controlled amount of vertical pressure until it fails, giving an idea of its performance under real conditions.

The result of the test is represented in terms of force per unit length, usually expressed in pounds per inch (lb/in) or kilonewtons per meter (kN/m).

Edge Crush Test = Maximum Load at Failure / Width of Specimen

Through better packaging design, ECT ensures safer shipment of bulbs by reducing the breaks and failures of products that could occur due to transportation. Additionally, ECT ensures that companies can minimize material usage while trying to reduce waste, which also decreases the cost of packaging.

In addition, the edge crush strength of packaging measured with high accuracy enables companies to fine-tune their materials for particular needs. Whether lightweight bulbs or larger, more fragile glass products, the ECT allows manufacturers to make packaging that can endure specific pressures expected during transportation.

ECT enhances packaging durability by ensuring that the corrugated material used can withstand stacking pressure without collapsing, which reduces the damage to bulbs while in transit and storage.

Yes, ECT is suitable for testing the packaging of any fragile products, such as electronics, glassware, and any other products requiring robust packaging solutions.

The main industries that benefit from ECT include electronics, glassware, automotive, and any sector that makes use of tough corrugated packaging.

With Presto's Edge Crush Tester, a company can be sure to design better packaging, minimize the breakage of the product, and ensure the safety of fragile goods while in transit and storage.

Contact us:

Phone: +919210903903

Email: info@prestogroup.com

Our latest product catalogue cum company profile is now

available to download. Where should we send your FREE copy?